-80℃~-150℃ metal treatment box

use

1. For cold assembly

What is cold assembly: Cold assembly is the use of refrigeration medium to cool the parts that need to be loaded into the base hole first, so that its outline size shrinks, resulting in assembly gaps, so that the parts can be easily assembled.

2. Used for cryogenic treatment in heat treatment

What is cryogenic treatment: When the metal is hardened in heat treatment to the cooling process, the alloy and carbon dissolve and combine and diffuse to form Austenite. During the cooling process, Martensite is formed due to the low temperature compression, and the final transition point (MF) of martensite is very low. Therefore, quenching and cooling to room temperature will leave a large amount of austenite, thus reducing the hardness, wear resistance and service life of the metal, while because of the high brittleness of austenite and easy to cause metal fragmentation, in addition, there are many physical properties, especially thermal properties and magnetic decline.

The role of cryogenic treatment

* Improve the hardness and strength of the workpiece

* Ensure the dimensional accuracy of the workpiece

* Improve wear resistance of the workpiece

* Improve the impact toughness of the workpiece

* Improve the internal stress distribution of the workpiece

* Improve fatigue strength

* Improve corrosion resistance of the workpiece

peculiarity

1. Temperature range: -80℃~-140℃;

2. Heat dissipation mode: air cooling, water cooling can be selected according to customer needs;

3. Control mode: PLC+ touch screen control can be selected;

4. Refrigeration method: cascade refrigeration, cooling capacity 1~2000KW for choice;

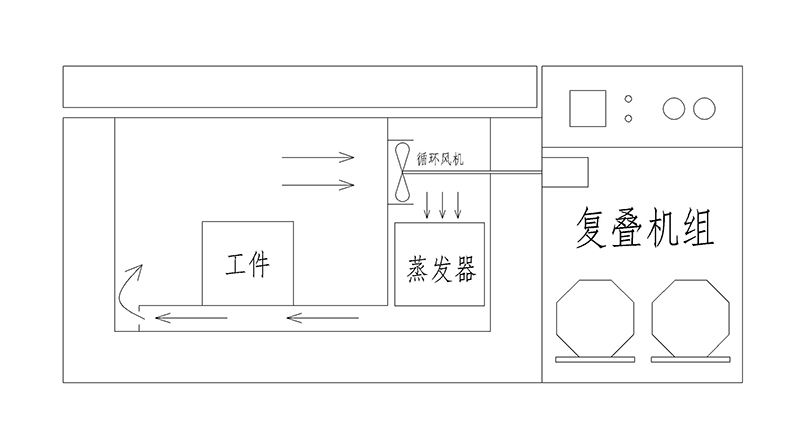

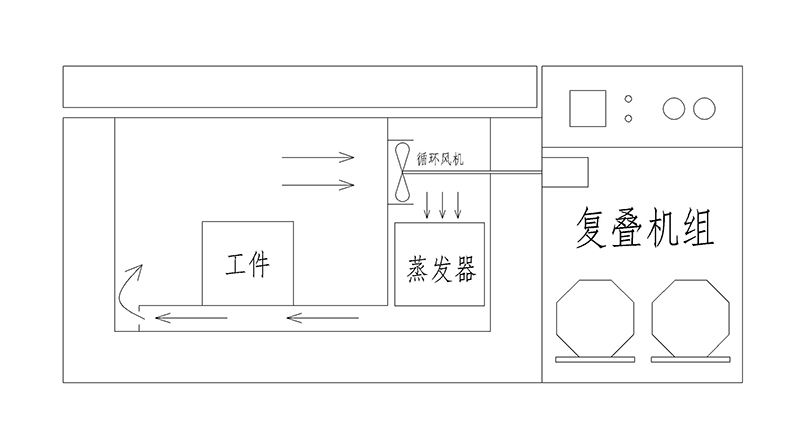

5. The cold air in the box is forced convection by circulating fan to achieve rapid cooling;

6. Optional automatic opening and closing control equipment.

Because the ultra-low temperature metal treatment box is widely used in the industry, and the use is also different, it cannot be fixed, and it is usually tailored according to the user's requirements (required temperature, volume, material processed, cooling time, various heat losses, etc.).

1, according to the principle of thermal expansion and contraction, the frozen workpiece has a certain amount of contraction,

And then to achieve the purpose of assembly.

(Linear expansion coefficient of steel: 11.2X106 m/degree)

2, the metal after low temperature treatment, the metallographic structure has changed, the performance has been improved,

After treatment, the wear resistance and dimensional stability of the metal work are increased, and the service life of the tool and the die are increased exponentially.

(1) The residual austenite content in metal materials can be greatly reduced

Low to less than 3%, so that the stability of the size can be greatly improved.

(2) The metal structure is uniform and subtle in the matrix

Dispersion of carbonized matter precipitates. This precipitation phenomenon of carbonized matter will significantly improve the wear resistance and friction performance of the metal, and the hardness will also increase, and will directly improve the life of the wear part.

Experiments show that:

After low temperature treatment, the wear resistance of high speed steel tools is increased by 3 times.

The friction coefficient is reduced by 20%, the hardness is increased by 1-4 times, and the service life is improved

Increased 1-3 times. Experiments with other materials have also shown extended service life

Long similar results. The profound changes in these two aspects make low temperature cold treatment technology

The technique has unique advantages.

|

型號

|

工作溫度

(℃)

|

制冷方式

|

負(fù)載:鋼

(kg/小時)

|

制冷量(KW)

|

能耗(kw)

|

容積(升)

|

|

HY-80-6SJ

|

-60~-80

|

雙

機(jī)

復(fù)

疊

|

70

|

1

|

6

|

150

|

|

HY-80-12SJ

|

140

|

2

|

12

|

500

|

|

HY-80-30SJ

|

350

|

5

|

30

|

1000

|

|

HY-80-60SJ

|

700

|

10

|

60

|

2000

|

|

HY-80-180SJ

|

2100

|

30

|

180

|

5000

|

|

HY-120-4TJ

|

-80~-120

|

三

機(jī)

復(fù)

疊

|

55

|

1

|

8

|

150

|

|

HY-120-8TJ

|

110

|

2

|

16

|

500

|

|

HY-120-16TJ

|

60~120

|

5

|

40

|

1000

|

|

HY-120-32TJ

|

120~240

|

10

|

80

|

2000

|

|

HY-120-80TJ

|

360~720

|

30

|

240

|

5000

|

|

HY-140-8FJ

|

-100~-140

|

單

機(jī)

復(fù)

疊

|

40

|

1

|

8

|

150

|

|

HY-140-15FJ

|

120

|

3

|

24

|

500

|

|

HY-140-25FJ

|

200

|

5

|

40

|

1000

|

|

HY-140-100FJ

|

800

|

20

|

160

|

2000

|